The ISO 16232 and VDA 19.1 standards are international reference frameworks that define how to measure and ensure the cleanliness of industrial components, particularly in the automotive, aerospace, and medical industries.

Both standards establish methodologies to:

The ISO 16232 standard covers:

Interpretation of results according to the type of component

Types of extraction methods (spray, ultrasound, rinsing, combination)

Operating parameters (pressure, duration, temperature)

Filtration procedures

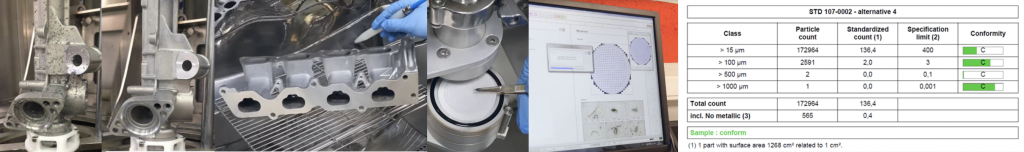

Particle analysis: number, size, type (metallic, non-metallic, fibers)

Our systems are designed from the outset to comply with these standards:

Machine design compatible with ISO/VDA controls

Particle separation through fine filtration

Monitoring of critical process parameters (pressure, temperature, timing)

Pre-process validation in the laboratory.

At WashTech, we design and manufacture equipment specifically engineered to meet precise cleanliness criteria.

High-precision rotary spray machines

Immersion and ultrasonic systems for extreme criteria

Fine filtration

Pre-process validation with internal testing

Equipment compatible with ISO 16232 / V