In the aerospace industry, every micron counts. WashTech designs washing solutions that meet the most demanding requirements in terms of technical cleaning, traceability, and process validation.

Our machines ensure the cleaning of your parts at different stages of the manufacturing process:

Components in the aerospace industry are made from a wide variety of materials such as Inconel, titanium, aluminum, and superalloys.

Just like the subsequent process, these metals must be taken into account when choosing the cleaning method to be used: chlorinated solvents, aqueous solutions, hydrocarbons, microemulsions…

WashTech machines in the aerospace industry are equipped with systems for continuous monitoring of process parameters connected to the PLC. This system allows report generation after each cycle and data logging, providing a standardized approach.

For this purpose, the operation of each sensor is essential (level, temperature, pressure, pH, conductivity).

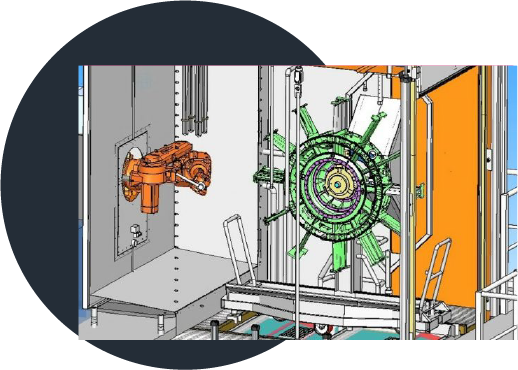

The design of tools and pallets tailored to the parts being processed is one of WashTech’s strengths. Proper placement of parts for cleaning and drying plays a key role in achieving optimal cleaning results.

To ensure reliable results, full automation of the cleaning process with machine intelligence—or even automatic loading/unloading of parts or pallets via peripheral equipment (robots, conveyors, loaders, lift tables, etc.)—helps reduce manual operations.

Cleaning complex and sensitive parts, such as transmission housings, requires that the cleaning fluid be identical or have similar properties to the fuel that will circulate in their systems (kerosene, MEK, Diestone…).

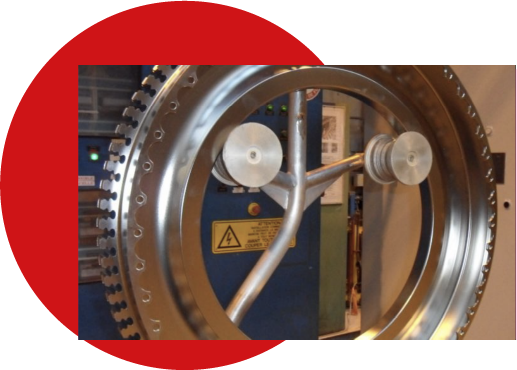

This type of cleaning equipment, operating in an explosive environment (ATEX), is an integral part of WashTech’s know-how.

Equipped with multiple rinse tanks to achieve the desired component cleanliness, continuous monitoring of bath conductivity from 0 to 200 µS ensures repeatability of the cleaning requirement.

WashTech machines implement devices that filter and reprocess washing and rinsing fluids for a zero-discharge solution.

Some examples of parts and components cleaned in the aerospace industry: