Immersion cleaning consists of submerging parts in a liquid bath —usually water with detergent or solvent— to dissolve and remove contaminants such as grease, oils, particles, or chemical residues. This process is enhanced through

It is an ideal solution for parts with complex shapes or areas inaccessible to direct spray.

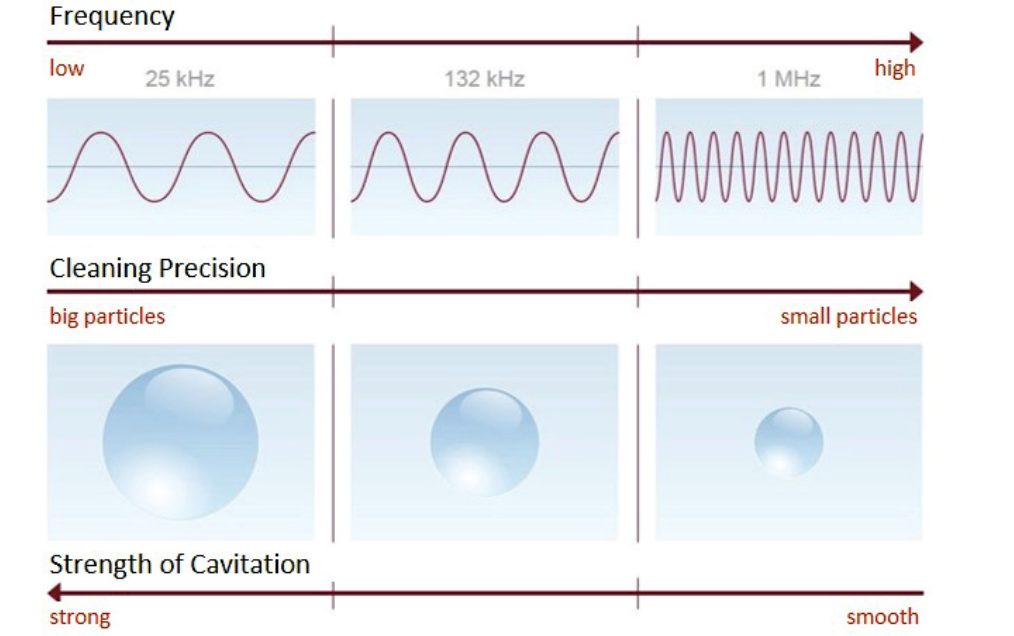

Ultrasonic technology introduces high-frequency sound waves into the bath. These waves generate microbubbles (cavitation) that collapse violently, removing impurities adhered to the surface of the part — even in deep cavities or blind holes.

This technology makes it possible to treat parts with complex geometries and to remove strongly adhered contamination.

WashTech offers 2 families

of ultrasonic washers

managed by WashTech.

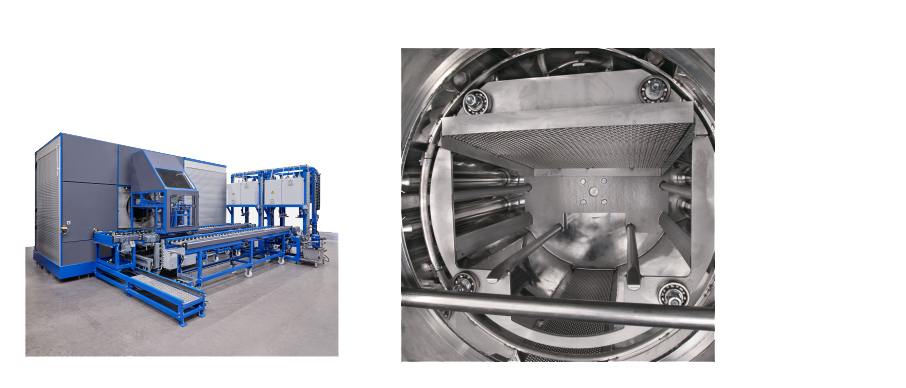

PowerJet – Vacuum Water

Immersion Machine

Machine designed for the most

advanced cleaning criteria: 3D printing,

optics, medical, semiconductors.

Multi-Tool Machine: supports spraying,

immersion, ultrasound, recirculation,

vapor, vacuum cycles (CNP), and

vacuum drying.

Solvacs – Solvent

Washing Machine

Machine suitable for applications with high organic contamination (oil, grease).

Optimal degreasing quality.

Low energy consumption.