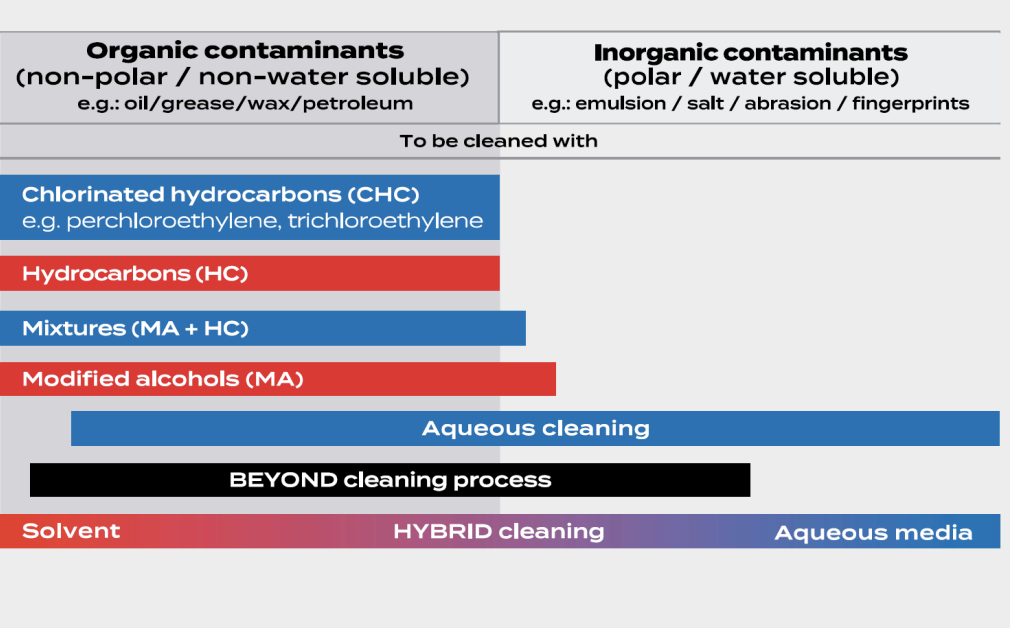

Solvent cleaning is a process used to remove organic contaminants such as oils, greases, waxes, and machining fluids from metal parts. This method is widely used in industries that require extreme and repeatable cleaning for highly contaminated components.

Higher Degreasing Power: Solvents easily dissolve organic contaminants.

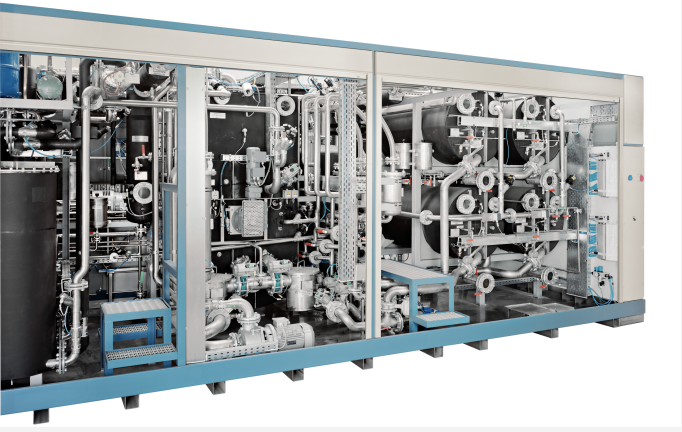

Closed Process: Integration of a distillation system within the machine allows continuous solvent recycling.

No Effluents: As the solvent is recycled internally, environmental impact is minimized.

Compatibility with Complex Geometries: Operating under vacuum allows treatment of extremely complex geometries.

Vacuum Chamber: The part is placed in a closed chamber and a vacuum is applied to eliminate any risk of solvent ignition.

Immersion Cleaning: The part is submerged in hot solvent. The solvent circulates within the chamber and is continuously filtered. Optionally, rinse tanks and ultrasonic modules can be added.

Vapor Cleaning: Solvent vapor is injected to ensure perfect degreasing of the part.

Vacuum Drying: The intense vacuum in the washing chamber promotes solvent evaporation and allows the part to be completely dried.

Internal Distillation: In parallel with the washing process, the solvent is distilled and continuously recycled, always ensuring cleaning with pure solvent.

Hybrid washing combines the advantages of solvent cleaning (high degreasing efficiency) with those of water-based cleaning (ability to remove inorganic contaminants such as salts, oxides, and combustion residues).

The Solvacs equipment is available in a hybrid version, allowing for extreme levels of cleanliness.