Simple or Forced Immersion Cleaning Machine with Ultrasonics and CNp

3 standard working chamber sizes. Cleaning by simple or specialized immersion method with ultrasonics.

Compatible with the Cyclic Nucleation Process (CNp).

Parts handled in bulk batches, stored, or on pallets.

Designed for high-quality cleaning requirements.

High processing capacity with low operating costs.

Manufactured by our partner LPW Reinigungssysteme GmbH in Germany.

The PowerJet cleaning machine is available in 3 standard dimensions depending on the size and volume of parts to be processed. For special applications, the working chamber can be custom-made.

The PowerJet allows the use of all known cleaning and drying processes according to the required cleaning specifications.

Its flexibility enables the treatment of heavily soiled parts as well as the disinfection of medical devices.

When applications require separation of each cleaning stage or when production pace demands saving processing and loading time, the PowerJet is available as a standard multi-chamber machine.

When operating in a closed loop, excellent fluid treatment is essential to achieve repeatable cleaning results and to regularly drain the bath.

Loading and unloading of the PowerJet system is fully automated with a conveyor integrated into the machine.

In multi-chamber machines, especially for final cleaning in a high-speed environment, it allows simultaneous loading and unloading of parallel chambers.

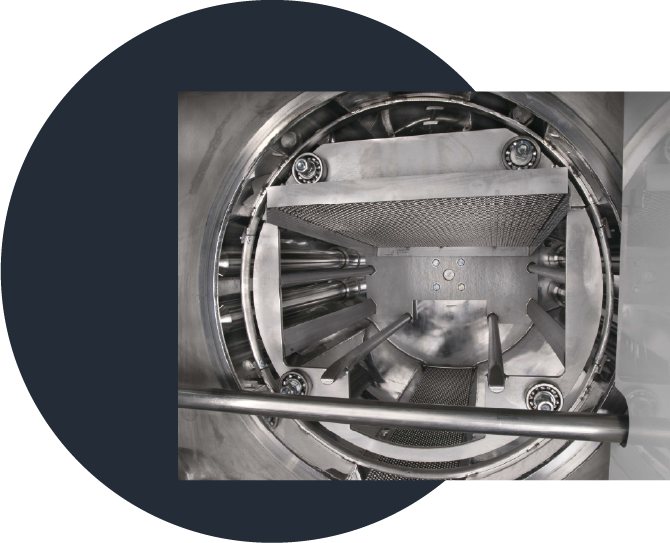

Forced immersion consists of constant pressure changes combined with basket rotation.

The chamber alternates between overpressure and vacuum, producing reverse flow variations to clean cavities and deep holes.

Ultrasonics propagate through the fluid, generating cavitation and microcurrents that enable parts cleaning. The lower the frequency, the more intense the action.

Depending on the material’s fragility and the adherence of contaminants, different frequencies are used:

CNp technology ensures ultra-efficient cleaning of complex geometries such as grooves, blind holes, and narrow channels without damaging the parts’ surfaces. Integrated into the PowerJet, CNp opens new cleaning possibilities in numerous fields:

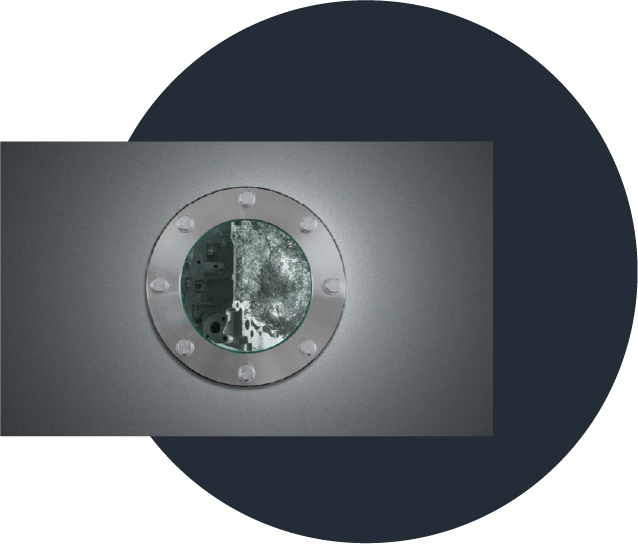

For highly sensitive cleaning applications, the PowerJet design itself is upgraded to serve as a transition door between the gray room and the cleanroom environment.

Both companies, LPW and WashTech, members of Surface Alliance, have been partners for 10 years.

WashTech ensures the representation of the PowerJet cleaning machine range in Mexico.