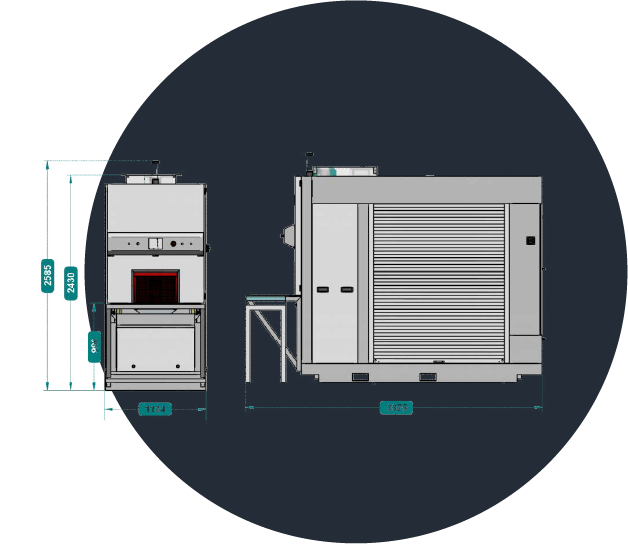

The MecanoJET allows the processing of medium and large loads, offering a capacity of four to six loads per hour.

The MecanoJET can process loads from 670 x 480 x 300 mm up to a custom-made drum.

Its smaller sibling, the MecanoJET Compact, can accommodate baskets or pallets with usable dimensions of 530 x 320 x 200 mm.

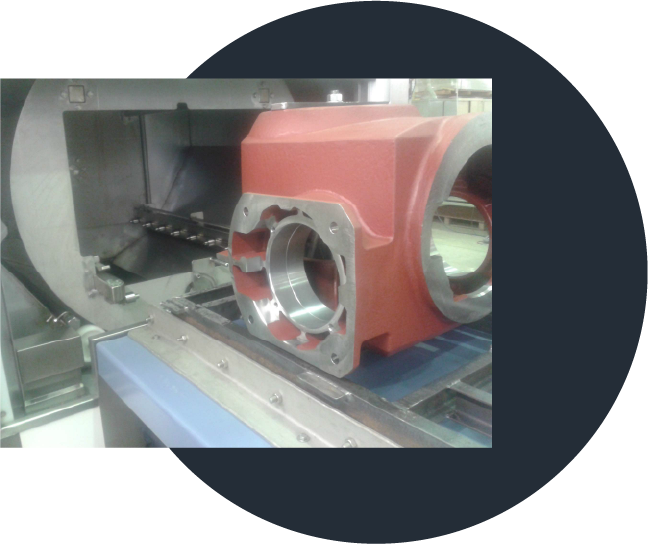

For each cycle recipe, the MecanoJET offers the option to select between full drum rotation or oscillation.

All equipment and functions are integrated within the maintenance compartment of the MecanoJET. Its reinforced chassis, which includes forklift passages, allows for easy installation in the production workshop.

To provide excellent degreasing performance, the MecanoJET features two separate tanks.

Cleaning recipes are modular according to the type of treatment required and the parts to be cleaned.

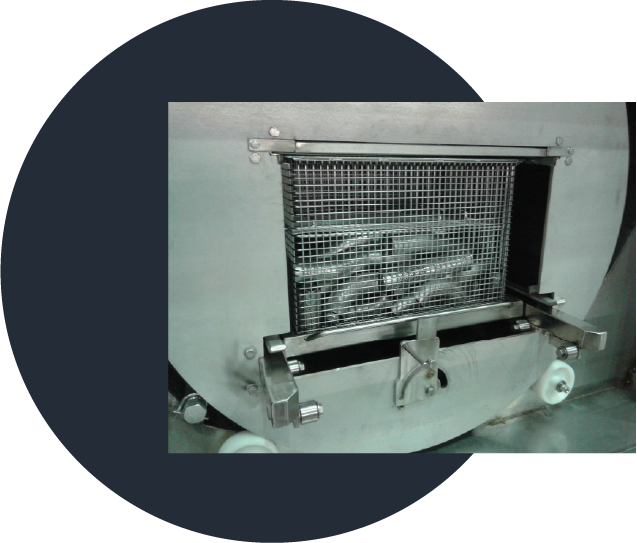

In addition to classic mesh baskets or containers, the MecanoJET allows for the treatment of parts arranged and organized on specific pallets.

WashTech ensures CAD design through its integrated engineering office, as well as the production of these specific fixtures.

To simplify the loading/unloading flow, complementary equipment can be easily integrated with the degreasing machine.

The MecanoJET is equipped with a PLC with a touchscreen that allows operators to use the machine easily and intuitively.

The MecanoJET is available in a cross version (inlet area / outlet area). Mimicking the flow principle of a washing tunnel, the rotation/oscillation ensures excellent overall performance while facilitating the drying of the parts to be processed.