Request a quote

The MecanoFAST ensures a very high cleaning cadence, from 15 to 60 seconds depending on the type and complexity of the part.

Designed to integrate easily into the production flow, the MecanoFAST allows a smooth connection between upstream and downstream manufacturing processes.

The batch cleaning concept creates significant interruptions in the production flow, slowing down production and generating inventory buildup. The MecanoFAST process takes a different approach, using the one-piece flow concept with a short cycle time.

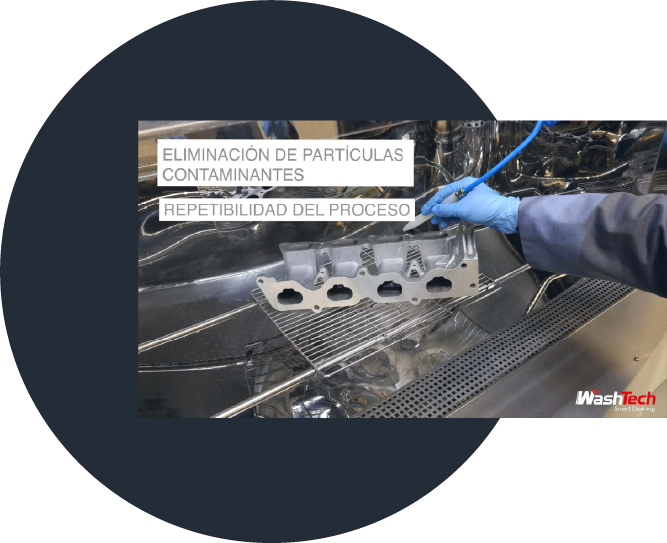

The part support and cleaning/drying tools are designed in 3D and manufactured according to the part drawings and critical areas.

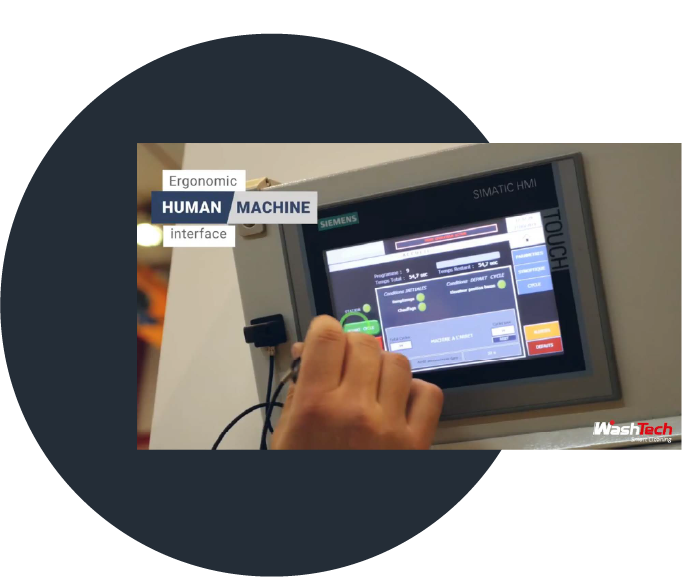

The MecanoFAST integrates high-quality components from premium brands.

The MecanoFAST system consumes 2 times less energy and approximately 4 times less water than a traditional carousel tunnel-type system.

Does your assembly or production line operate manually or fully automated?

The MecanoFAST system features wide front access for fast and efficient loading/unloading.

Quick change > tool replacement in less than 5 minutes

We support you through validation tests and laboratory analysis.

Large removable panels ensure safe and easy access to the filtration system, tank, and other moving parts.