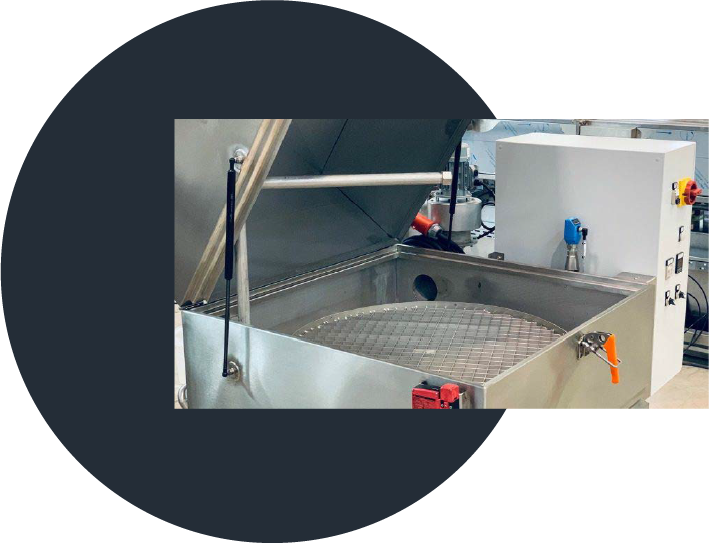

The ECO mechanical parts degreasing machine comes in a range of 3 models depending on the dimensions, weight, and quantity of parts to be cleaned:

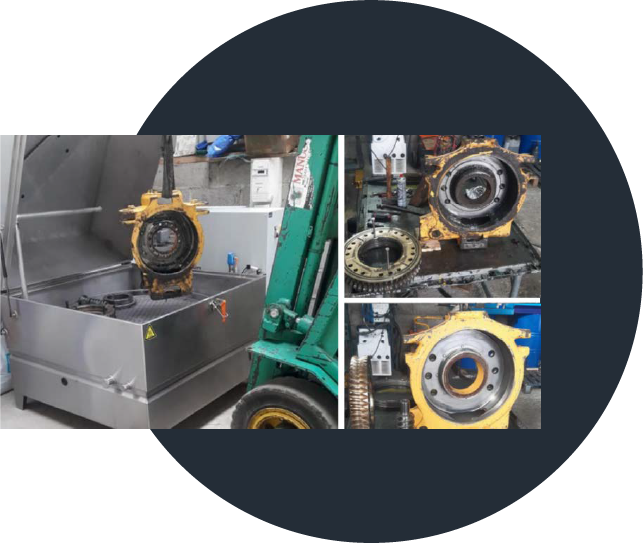

IC2: Ø780 mm – H450 mm – max 150 kg

IC3: Ø900 mm – H550 mm – max 300 kg

IC4: Ø1100 mm – H700 mm – max 500 kg

A long-standing product in our range, its robustness has been tested in numerous heavy vehicle garages and maintenance workshops.

All stages of the cleaning cycle are performed automatically according to preset timings.

The cycle can also include fully automated drying of the parts.

The cleaning fluid is used in a closed loop and filtered at multiple levels to collect contaminants and protect the washing pump.

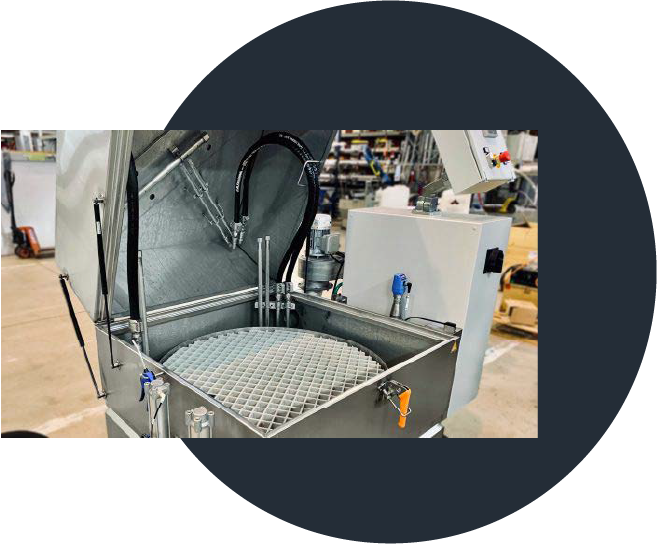

In addition to automatic mode, the ECO can include a manual mode for performing targeted action on complex areas of the parts.

Before finishing or painting, an optimal and repeatable rinse after the washing stage is essential. For this type of application, the ECO can include an additional module that allows rinsing of the parts with clean water.

There are numerous options that can be integrated depending on the application, whether essential for the process or to simplify maintenance.