The cleaning of industrial parts is key to ensuring quality and productivity across various industrial sectors. WashTech, based in Querétaro, Mexico, leads the way in advanced industrial cleaning solutions, standing out for its innovation in one-piece flow washing systems.

In this article, we’ll explain the differences between these two technologies, highlighting how each one addresses specific needs. If you’re looking to optimize your industrial processes, keep reading to find the ideal solution for your company.

In high-demand industries such as automotive, washing tunnels have historically been used to meet the need for cleaning large volumes of parts. These systems, once produced by Surface Alliance, successfully served industry requirements for decades. However, they are becoming obsolete for several reasons:

These characteristics make washing tunnels an increasingly outdated solution.

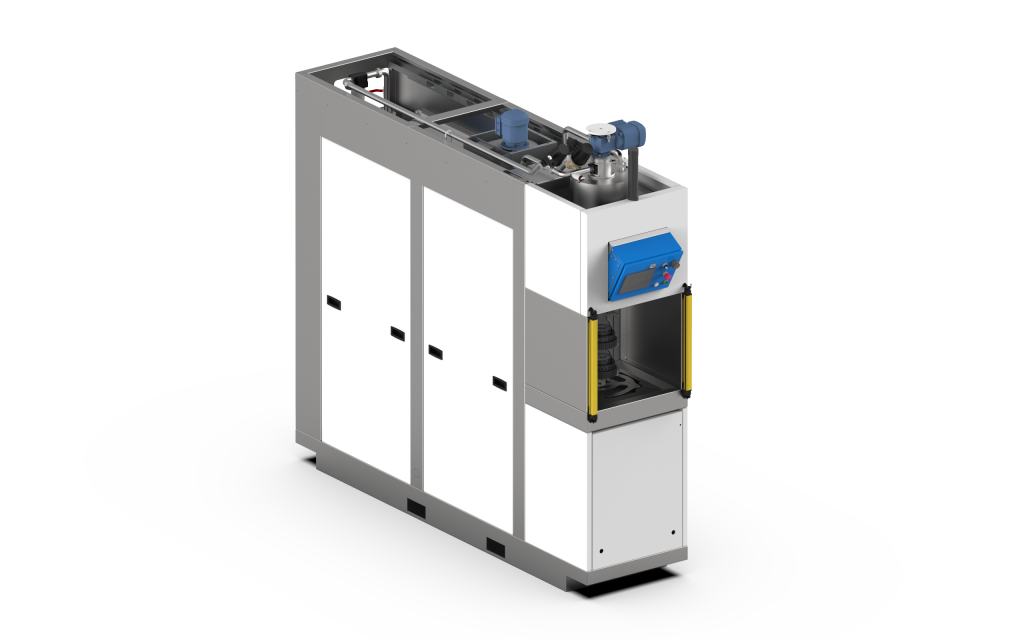

MecanoFast is a compact system specifically designed to meet the cleaning demands of industries that require high precision and space optimization. Ideal for critical parts used in sectors like automotive, this equipment combines efficiency, speed, and compliance with the most stringent standards.

Main Features:

MecanoFast not only adapts to technical cleaning needs for sensitive parts but also enables detailed process control, ensuring the reliability and consistency demanded by sectors like turbine manufacturing, transmission components, and engine production.

| Characteristic | Washing Tunnels | MecanoFast |

|---|---|---|

| Capacity | Mass production | Mass production |

| Space required | Large infrastructure needed | Compact design (2 m²) |

| Cleaning speed | Continuous process | One-piece flow cycle in 30 seconds |

| Resource consumption | High energy, water, and detergent use | Low energy and supply consumption |

| Applications | High-volume, low-cleanliness requirements | Precise cleaning for high-volume, critical parts |

Production Volume: Today, the only real advantage of washing tunnels lies in very high-volume applications with low cleanliness criteria. In many cases, twin MecanoFast systems can match this capacity at a lower acquisition and operating cost.

Space Efficiency: MecanoFast adapts to smaller areas, while tunnels require extensive infrastructure.

Cost Efficiency: MecanoFast drastically reduces operational costs thanks to its energy efficiency and low maintenance design.

WashTech Smart Cleaning: Innovation from Querétaro

From Querétaro, Mexico, and serving the entire continent, WashTech provides advanced solutions that optimize industrial processes. Learn more on our official website washtech.com.mx/es or follow us on LinkedIn to stay up to date with our innovations.

The choice between washing tunnels and MecanoFast depends on the specific needs of your operation. Both systems offer unique advantages that can transform your industrial cleaning processes.

Contact us today and take your productivity to the next level!