Degreasing is the process by which fats, oils, and organic residues are removed from the surface of parts.

It is an essential preliminary step to ensure the quality of subsequent processes such as:

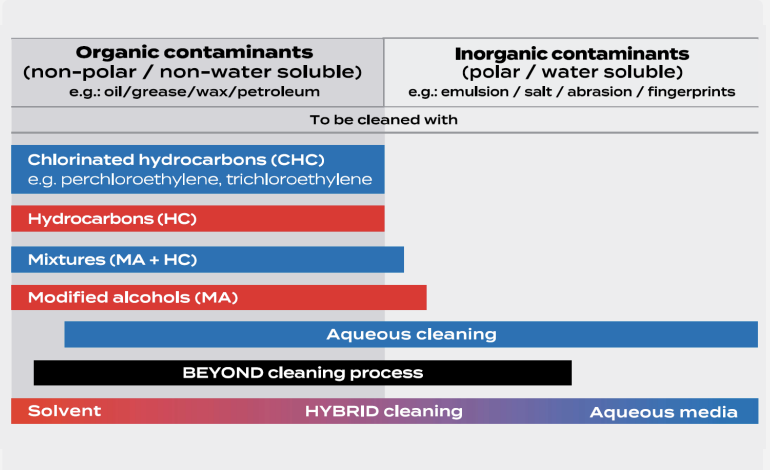

A highly efficient method for removing heavy oils, waxes, and strongly adhered greases. It uses hydrocarbons, modified alcohols, or chlorinated solvents.

Advantages

Unmatched dissolving power

Deep cleaning of complex geometries

Fast and residue-free

Continuous and efficient extraction of dissolved compounds

Consumable usage

Uses alkaline or neutral solutions

with surfactants that “break down” grease.

Advantages

Limited initial investment

Compatible with mass production

Effective cleaning of non-organic compounds

At WashTech we design customized degreasing equipment tailored to your needs:

At WashTech, we develop customized

degreasing equipment tailored to your needs:

Solvent-based equipment

Water-based equipment, by spraying or immersion

Hybrid water systemsa