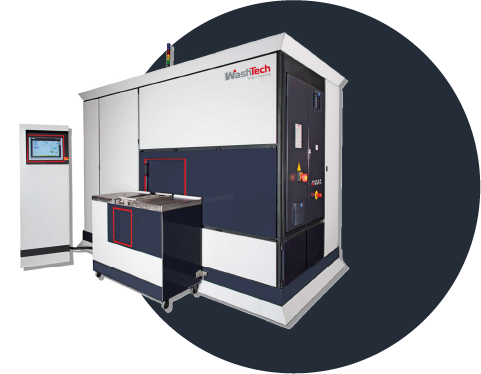

The SOLvent VACuum System, the SOLVACS vacuum degreasing machine, meets the highest standards for residue-free cleaning and degreasing and drying performance.

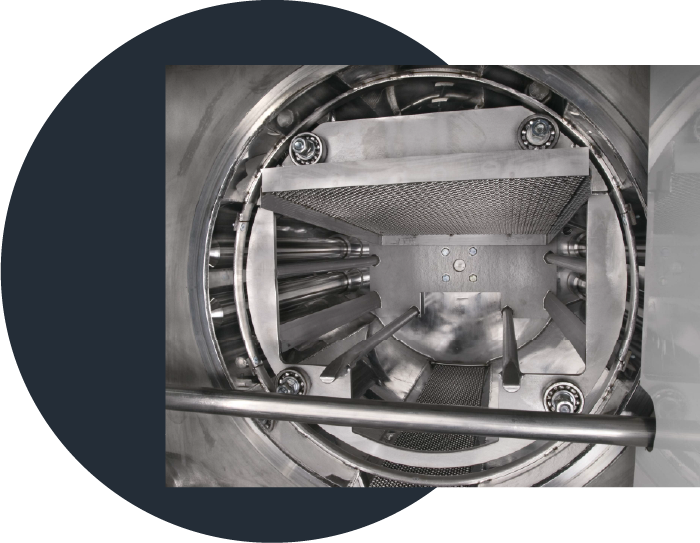

The entire system in contact with the solvent (<100 mbar) operates under vacuum, allowing cleaning at a temperature above the solvent’s flash point, both during immersion and in the vapor phase.

For continuous three-shift operation without interruption, the machine includes a secondary-circuit cooling heat exchanger to increase cooling capacity.

The TWIN SAFETY GUARD continuously monitors the solvent’s flash point and vacuum level through dual hardware and software safety.

The SOLVACS vacuum degreasing machine is available in 5 standard usable dimensions according to the size and volume of the parts to be processed.

For special applications, the working chamber can be custom-made.

More than just a degreasing machine, the SOLVACS integrates continuous solvent distillation to ensure optimal lifespan and repeatable results.

Additionally, an extra distillation step minimizes the solvent content (<10%) in the discharged residues.

Water and other substances are automatically removed at low boiling temperatures through the desaturation process.

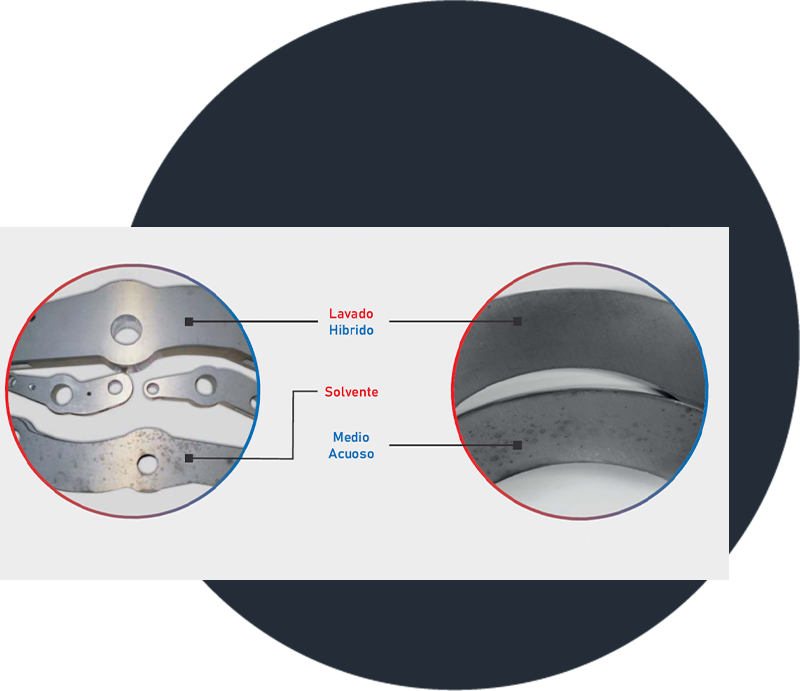

The Hybrid SOLVACS enables residue-free cleaning by combining the action of solvent and detergent to remove both organic and inorganic contaminants.

This is especially relevant for vacuum deposition treatment processes (plasma, nitriding, etc.).

HEMO GmbH, as the inventor of the technology, has full control over the process.

To provide local service in Spanish and keep the machine in perfect operating condition, monitoring and maintenance of SOLVACS machines installed in Mexico are carried out by WashTech’s after-sales service.

Both companies, HEMO GmbH and WashTech, members of Surface Alliance, have been partners for 10 years.

WashTech ensures the representation of the SOLVACS cleaning machine range in Mexico.