Widely used in high-cadence applications, the degreasing tunnel can be adapted according to the application and allows the integration of multiple modules for the successive treatment of parts.

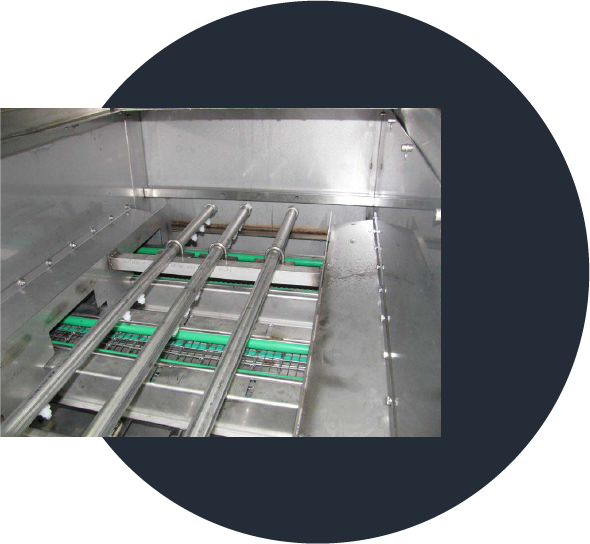

For effective cleaning and drying, the usable dimensions of the tunnel are defined according to the geometry and size of the parts to be treated.

For the treatment of multiple part references, especially in general industry sectors, the degreasing tunnel integrates a stainless steel mesh belt that accommodates a variety of parts.

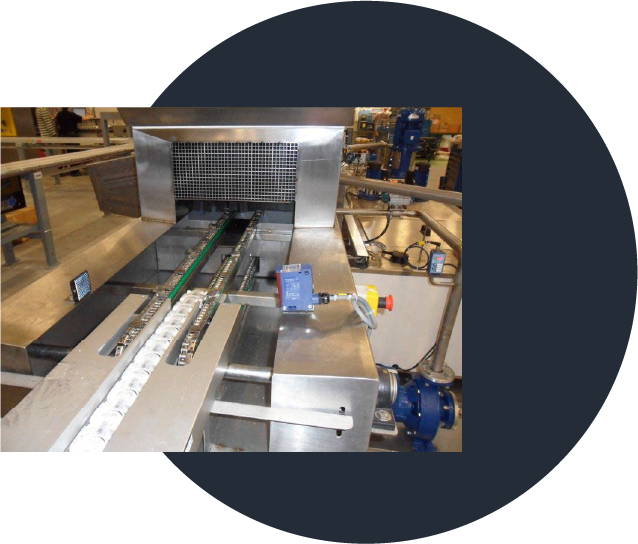

Two stainless steel carrier chains with hollow links allow the movement of existing part-support pallets. Fed by a first conveyor at the tunnel entrance, a second at the exit ensures the return of pallets to the next operation.

Specific supports adapted to the parts to be cleaned are integrated into the tunnel conveyor. This type of conveyor allows:

Continuous flow cleaning of parts meets the highest production cadences, especially in the automotive sector.

In the case of a standalone tunnel, a transport loop equipped with shuttles allows moving and grouping the loading and unloading stations, circulating pallets or baskets in a loop.

To ensure optimal accessibility during maintenance operations, each module is equipped with a lid with a safety switch to access the chambers.

Thanks to our experience with complex parts, WashTech has developed special devices integrated into the cleaning tunnel for focused mechanical action.

WashTech’s DNA lies in adapting our machines to our customers’ specific cleaning challenges.

This gigantic tunnel, over 18 meters long and 8 meters wide, capable of cleaning more than four hundred different part references, is the perfect example.

Our engineering and production teams work together to provide you with the right solution for your part cleaning challenges.