Several companies in the heat treatment sector have already requested our services for cleaning batches of mechanical parts after oil quenching or before tempering.

Maximum load capacity: 2.5 tons

Contamination before treatment: full oil, emulsion, particles, salts, oxides.

Residual contamination after heat treatment: quenching oil, salts.

Result achieved: completely free of contamination and marks, and dry upon exiting the machine.

Throughput: 1 to 6 batches per hour

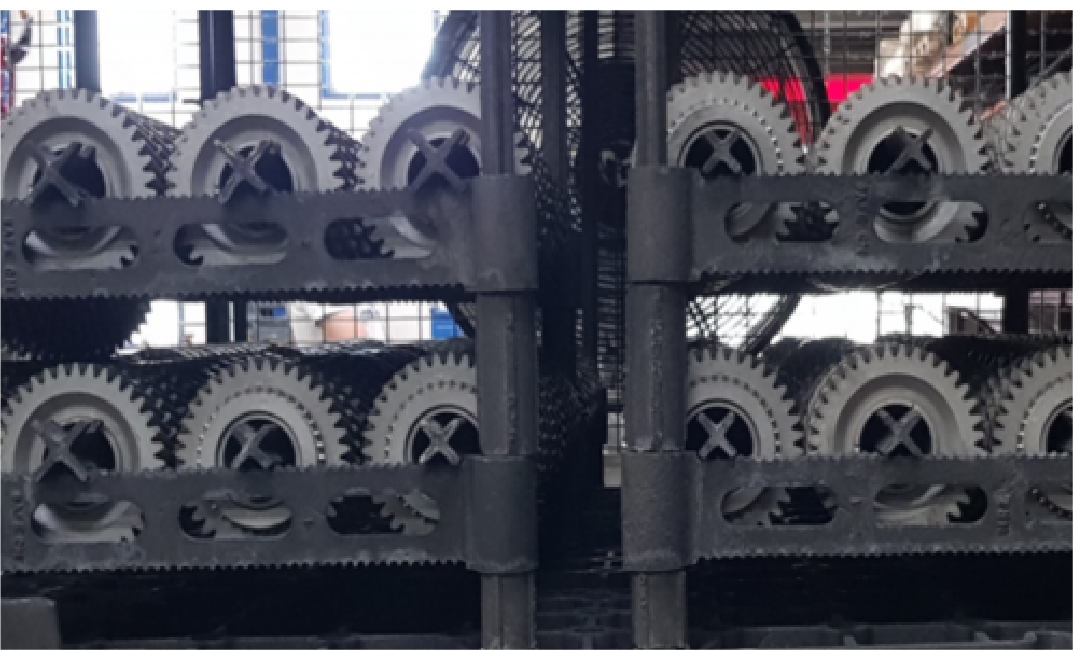

The machine is specifically designed to fit the customer’s basket loader. The batch rotates while being cleaned on all sides using calibrated spray ramps. A coalescence degreasing system in each bath ensures oil separation, guaranteeing reproducible results and prolonged bath life.

Cleaning process: wash → rinse(s) → blow-off → drying.

The SOLVACS Hybrid technology enables completely residue-free cleaning. It combines the action of solvent and water to remove all types of organic and inorganic contaminants, ensuring full compatibility with the materials of the parts. This solution is especially suitable for vacuum deposition treatment operations (such as plasma or nitriding).

Additional option: recovery of furnace heat to power the cleaning machine (Heat Transfer Waste Recovery – HTWR).